3D Workshop

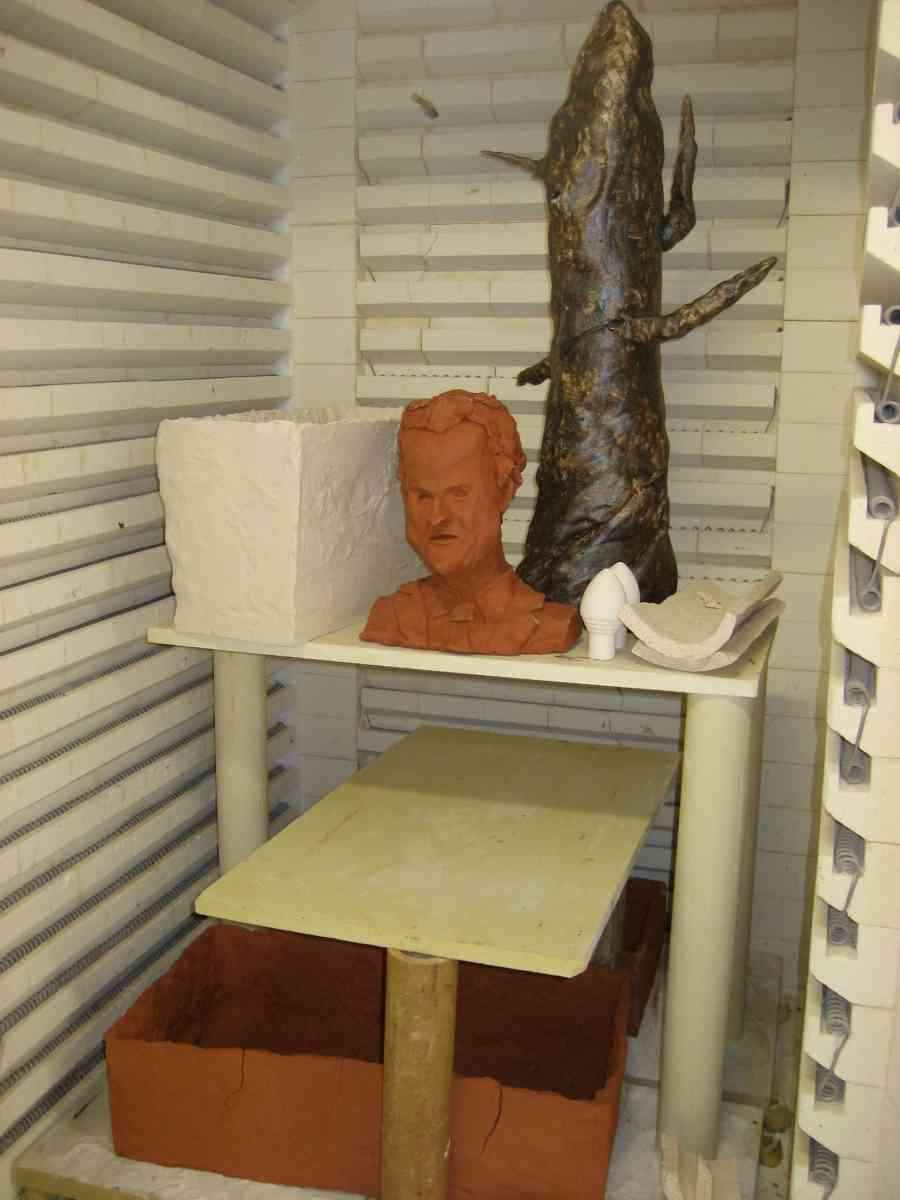

Ceramics studio

The ceramics studio comprises a kiln room and studios with slab-rolling bench and jigger-jolly machine for pottery production. The facilities also include a 5ft kiln, enabling students to make ambitious, large-scale ceramic works. A full range of ceramic processes are available, supported by expert staff, including slip casting, press moulding, slab building, glazing, decals and mould-making.

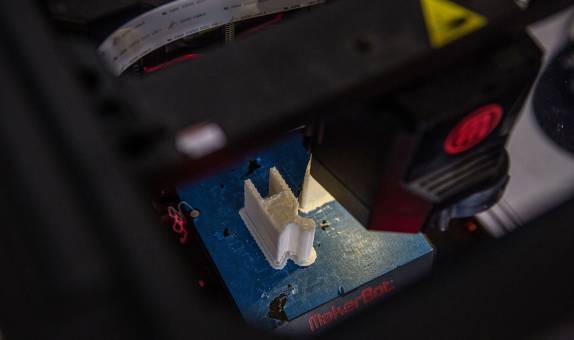

Digital suite

This area houses our digital equipment including; Zund plotter/cutters, laser engravers and a 4-Axis CNC milling machine. We also have a hackSpace with 3D printers, 3D scanners, CAD and Arduino stations. The hackSpace enables students to learn, explore, experiment, invent, innovate and transform the 2D into 3D, bringing ideas to life using cutting-edge technologies.

Metal work

The metal work area is dedicated to realising creative ideas in a range of metals. Students learn a variety of techniques, from traditional toolmaking to working with high-tech digital machinery. As well as a hand tools area, we have equipment that enables high-quality sheet metal work, milling, tube and rod work, two industrial lathes and a CNC digital plasma cutter.

Model making

This space is dedicated to the making of small-scale constructions, such as architects' models. Students can work in wood, plastics and various other model-making materials such as blue foam and laminated cardboards. Bench spaces within this area enable projects to be stored and worked on whilst design and construction is completed.

Plaster room

This space is used to undertake a variety of different types of mould-making and casting, from the use of traditional techniques to more experimental approaches utilising modern technologies. The plaster room is a place to explore different surface treatments and textures and to create form and space within the scope of materialising ideas.

The forge and foundry

Students at Kingston are in the privileged position of being able to learn the traditional methods of foundry work including the lost wax process and metal casting. They have the opportunity to experience the ancient alchemical process of pouring metal.

Welding bay

Our Welding Bay enables the fabrication of a wide range of structures, which require the ability to join, cut and shape metals. The space is equipped with MIG, TIG and ARC welding machinery, and processes are available for fusing both ferrous and non-ferrous metals.

Woodworking mill

The woodworking mill is dedicated to the preparation of materials prior to the finishing stages of a project. This involves processing both man-made and natural materials, often large in scale, using a variety of equipment: table and wall saws, planers, thicknessers, a drum sander, routers and a wide range of other machinery.